Liberty Primary Steel Selects Promecon GmbH McONAir Gas Monitoring Systems for their Whyalla Steelworks.

Ultra-Dynamics Pty Ltd is pleased to announce that Liberty Primary Steel selected the Promecon GmbH McONAIR Gas Flow Monitoring Systems for use in their Whyalla pellet plant. Accurate gas flow measurement is of critical importance in the kiln and drying furnace area of the process. It was the unrivalled accuracy and maintenance free reliability of the triboelectric technology of McONAIR that attracted Liberty to consider this technology.

The Liberty Primary Steel Whyalla Steelworks is located at Whyalla, South Australia, approximately 400 kilometres north-west of Adelaide. The plant has a production capacity of ~1.2Mtpa of steel using a Blast Furnace Steelmaking process.

It is an integrated steelworks using mainly magnetite iron ore-based feed, sourced from SIMEC Mining’s iron ore mines in the region.

Raw steel production from Whyalla during the year was 1.1 million tonnes. Billets produced from Whyalla and the Sydney and Laverton electric arc furnaces are rolled into a wide range of long products that are sold directly to external customers as well as downstream businesses: Australian Reinforcing Company (ARC), InfraBuild Construction Solutions, InfraBuild Steel Centre and InfraBuild Steel’s rod bar and wire mills.

Promecon Airflow Measurement

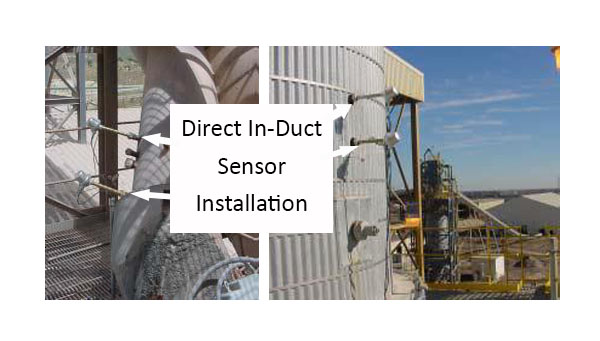

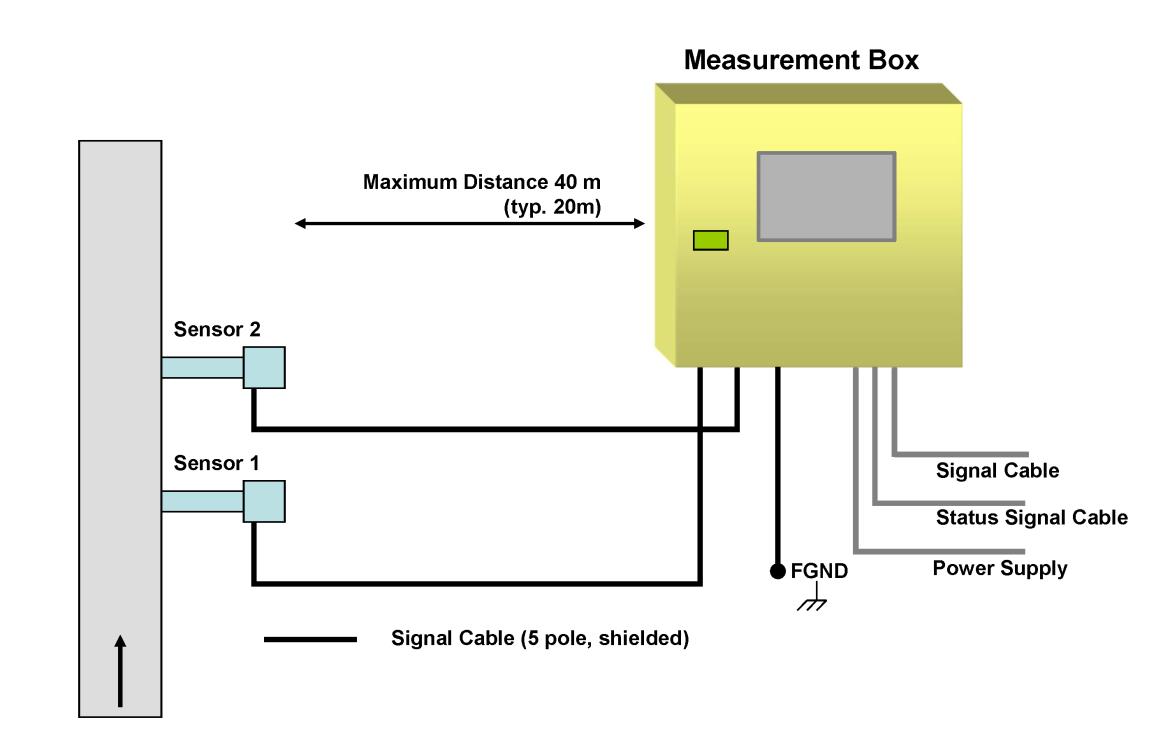

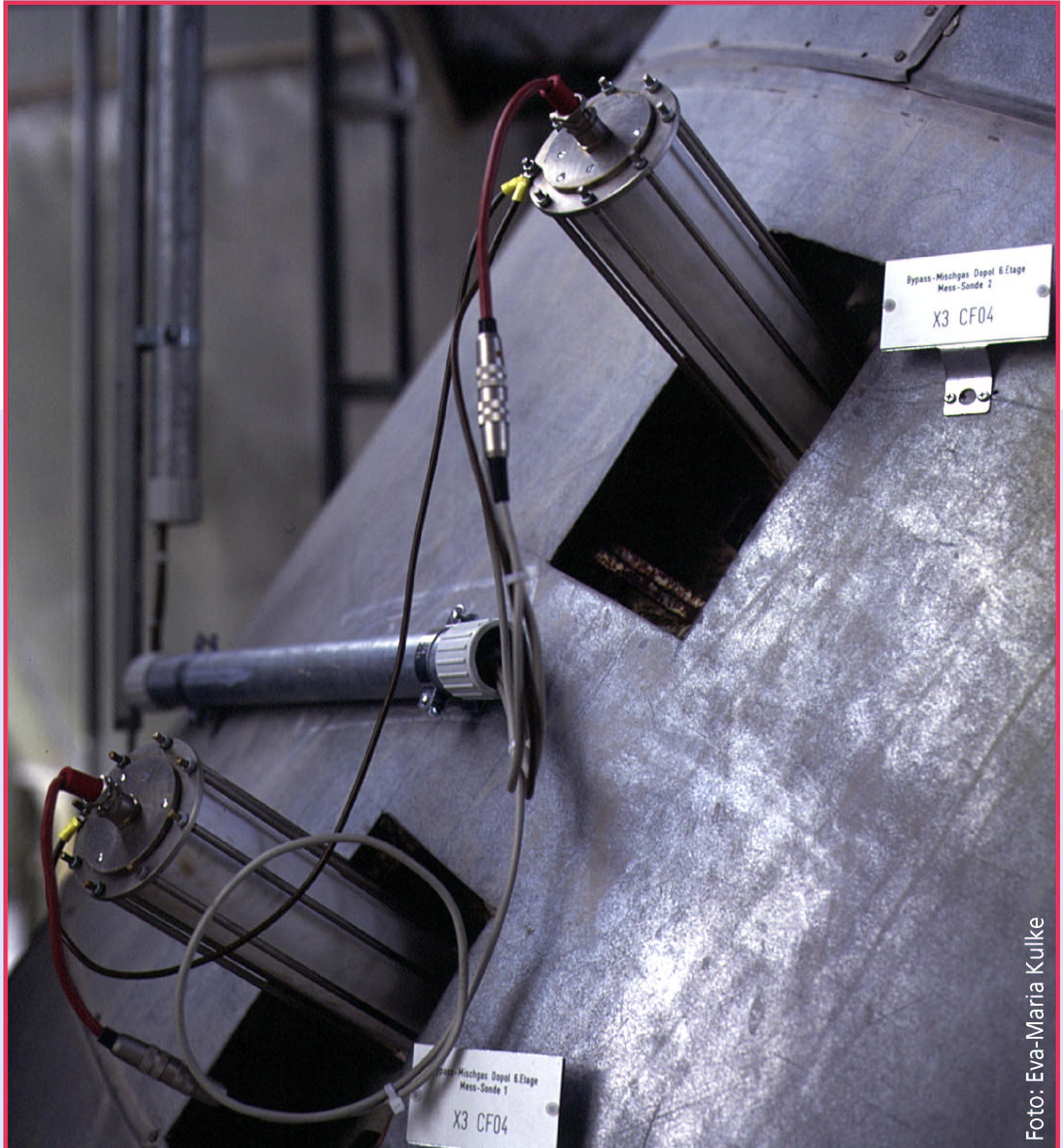

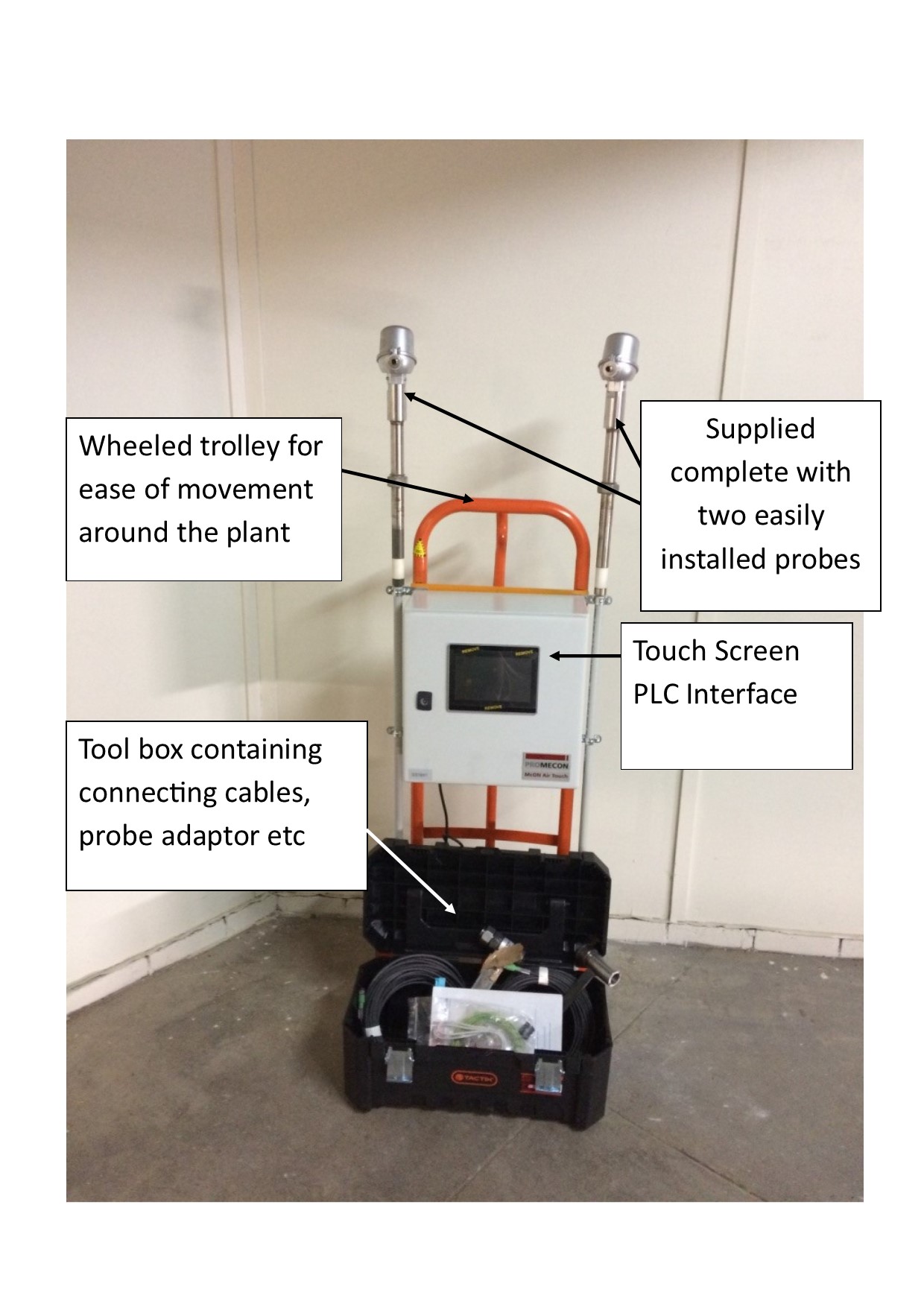

MECONTROL Air determines the absolute velocity of air or flue gas directly in pipes or ducts, even under extreme operating conditions such as high temperature as well as in high dust atmospheres. The velocity measurement is performed by a pair of sensors aligned parallel to the longitudinal axis of the pipe. A cross correlation technique is used to measure the time shift of matching signals. By using the cross sectional area of the duct as well as the temperature and pressure information the gas STP volume flow can be calculated on line.

The MECONTROL Air measurement is also designed to replace existing Venturi or other differential pressure systems because of its maintenance-free construction and the advantage of installation without any additional provisions and reconstruction measures. Most importantly: it does not need any reference measurement to be calibrated.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: