How you can save power and reduce costs in a cement plant.

Features and Benefits of Using the McONAir Gas Flow Measurement System:

Features and Benefits of Using the McONAir Gas Flow Measurement System:

- Measurement principle: cross correlation

- Typical accuracy: better +/- 2%

- Repeatability: better 0,05%

- Drift: 0%

- Maintenance/cleaning: none

- Linearity: 100%

- Hysteresis: none

- Calibration: none – “plug and play”

- Gas temperature: 10- 1000 °C (50 – 1800 °F)

- Dust load range: 10mg – 2000 g/m3

- Safety standards: SIL 2 according EN 61508 on demand

- No venturies necessary

How to reduce induced draft fan power costs To Save Power and Reduce Costs in a Cement Plant.

On vertical roller mills the Induced Draft fan is usually operated to achieve the minimum transportation air through the mill to secure a sufficient output of the finish product.

The measurement of this air amount (as specified by the mill manufacturer performance data) is measured on the clean gas side, after the Induced Draft fan and bag house filter (which necessarily includes leakage air) using a Differential Pressure sensor. The typical error of this type of sensor is 10- 15%. This means that in general day-to-day operation of the mill, ID fan set point is increased by a “safety factor” of +15% of air flow through the mill.

Reducing induced draft fan power costs by using a more accurate gas flow measurement technique.

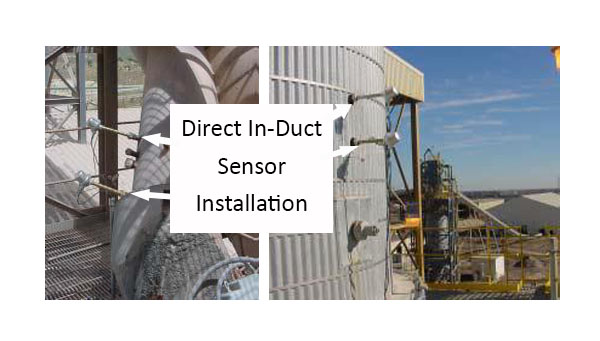

To measure the airflow on the raw, dirty gas side with the McONAir Triboelectric gas flow measurement system in place of the Differential Pressure System located on the clean gas side. The error of the McONAir is typically not more than +/-2%. Use of this more accurate sensor allows a typical reduction of 10% of air flow which can be measured and controlled more precisely. This therefore provides the opportunity to reduce electrical power costs on the Vertical Roller Mill fan motors.

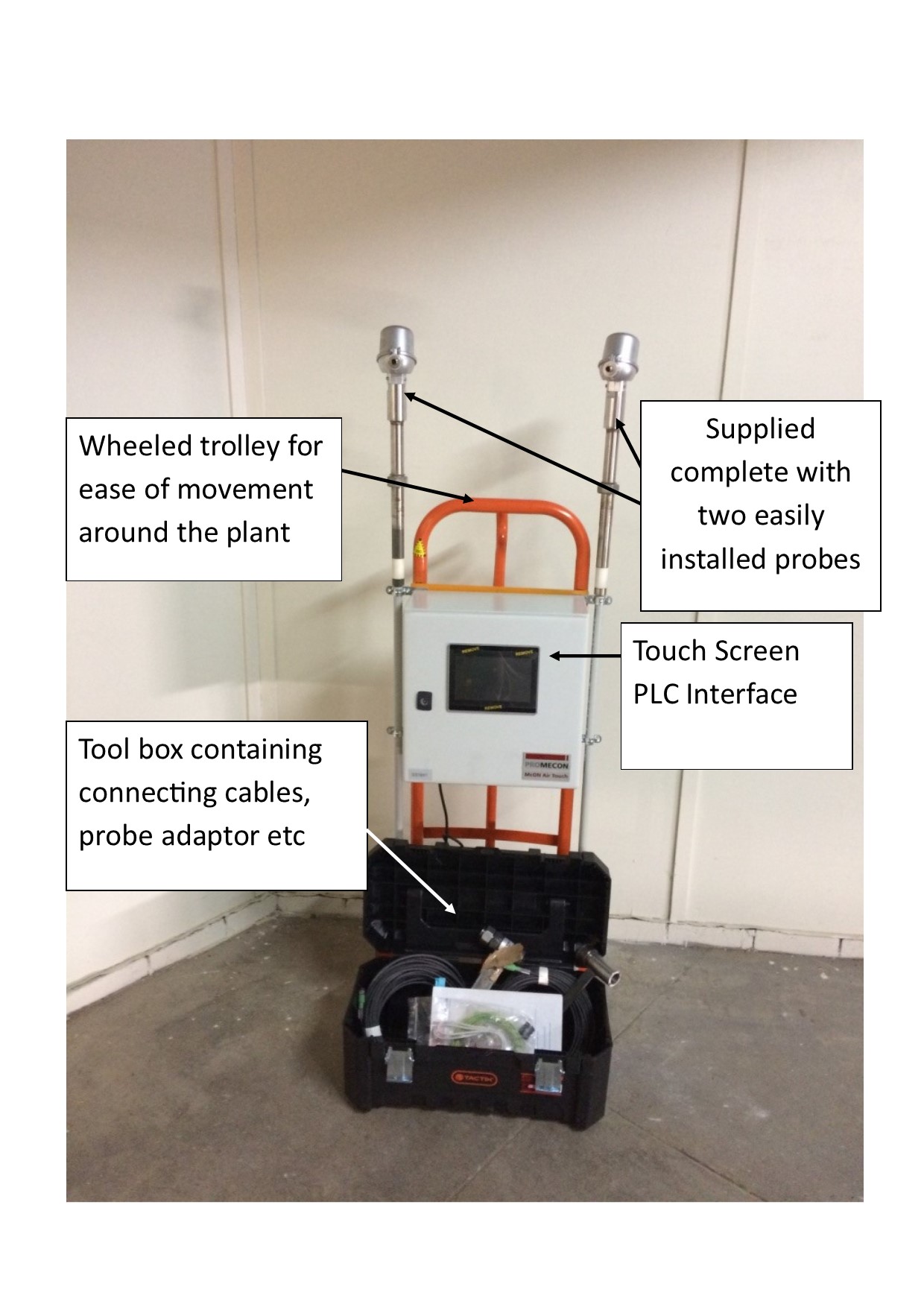

Ultra-Dynamics Pty Ltd can supply a portable McONAir unit on a short term rental basis so that plant gas flow surveys can be carried out with a view to identifying the best opportunities for application of the technology in strategic points in the cement plant process.

Promecon Airflow Measurement

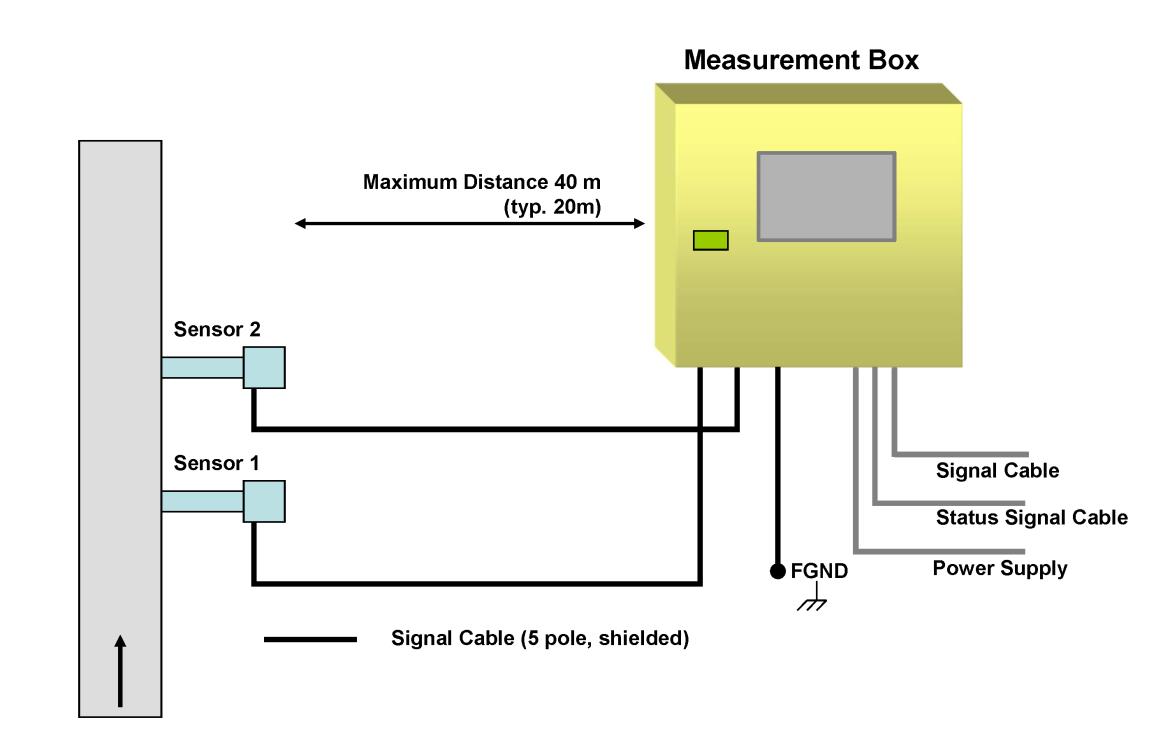

MECONTROL Air determines the absolute velocity of air or flue gas directly in pipes or ducts, even under extreme operating conditions such as high temperature as well as in high dust atmospheres. The velocity measurement is performed by a pair of sensors aligned parallel to the longitudinal axis of the pipe. A cross correlation technique is used to measure the time shift of matching signals. By using the cross sectional area of the duct as well as the temperature and pressure information the gas STP volume flow can be calculated on line.

The MECONTROL Air measurement is also designed to replace existing Venturi or other differential pressure systems because of its maintenance-free construction and the advantage of installation without any additional provisions and reconstruction measures. Most importantly: it does not need any reference measurement to be calibrated.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: