Contact us now to find out more. One of our experienced specialists would love to see how we can help you with your business process control measurement requirements.

ironSCAN On Conveyor MAGNETITE MONITOR

Description

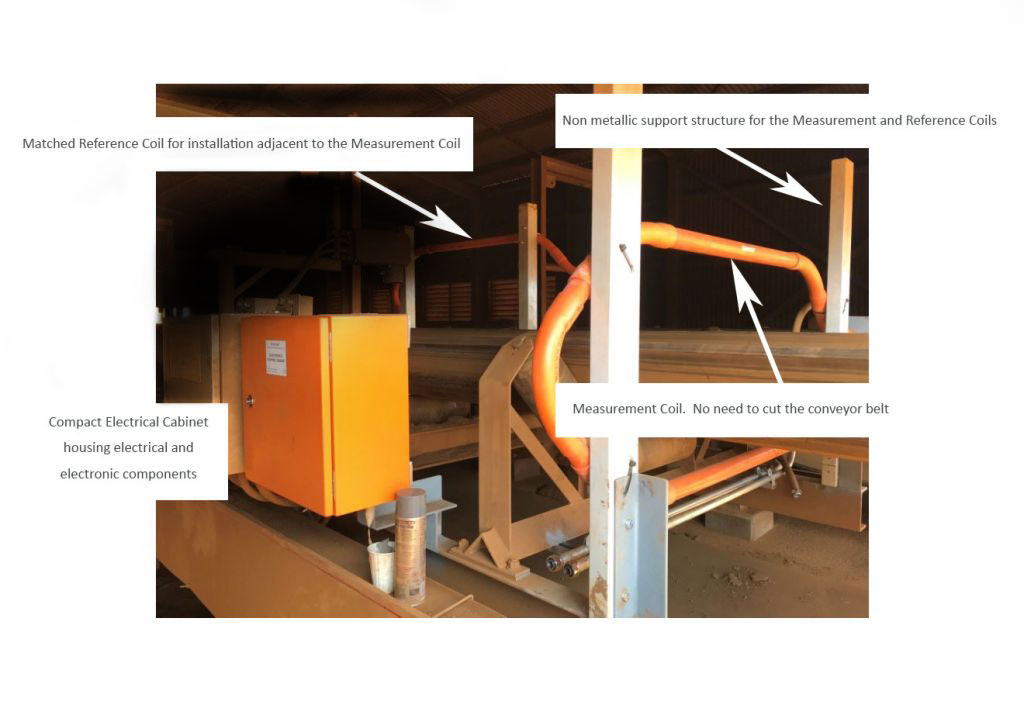

The system has been designed for installation on tonnage rated conveyor belts for the measurement of the metaliferrous content of crushed ore prior to processing. The system consists of an interrogation coil which is installed round the conveyor belt; a reference coil which is located adjacent to the interrogation coil and an Electronics Control Cabinet which houses all the electronic components. As the mineral content changes, these changes affect the electrical field of the measurement coil are is used to determine the metal content of the ore. The mineral content can then be output to the plant PLC for process control functions. Once the system has been installed, it has to be calibrated, which is usually carried out using an automatic sampling system if this is available. If an automatic sampling system is not available then stop belt sampling can also be used to calibrate the system.

The system has found to be useful in the iron ore industry for the measurement of metal content of ore prior to processing. The information provided by MAGNASAT is useful for process control purposes such as modulating feed rate to the crushing plant to ensure a consistent feed.

| Direct “on-belt” installation | interrogates the entire conveyor burdenencircling coil configuration |

| Easy set and calibration | “two point” calibration required stable calibration |

| Linear system response | |

| State of the art electronic design | ultimate precision of <1 x 10 m /kg Measurement of absolute mass flow compensation capability inbuilt temperature compensation |

| IP65 enclosures | suitable for field installation |

MAGNASAT measures the magnetic susceptibility of materials from the change that these materials cause to an alternating current (AC) magnetic field. Changes to the AC magnetic field are caused by a complex mix of eddy currents and the action of magnetic domains and the magnitude of these changes are dependent on the material’s magnetic and electrical properties as well as the quantity of material presented for measurement.

The System

Bench Top System

Density Gauge

Drill Core Analysis System