Reducing the Maintenance Costs of Your Load Cell Type Beltscales Using ultraWEIGH?

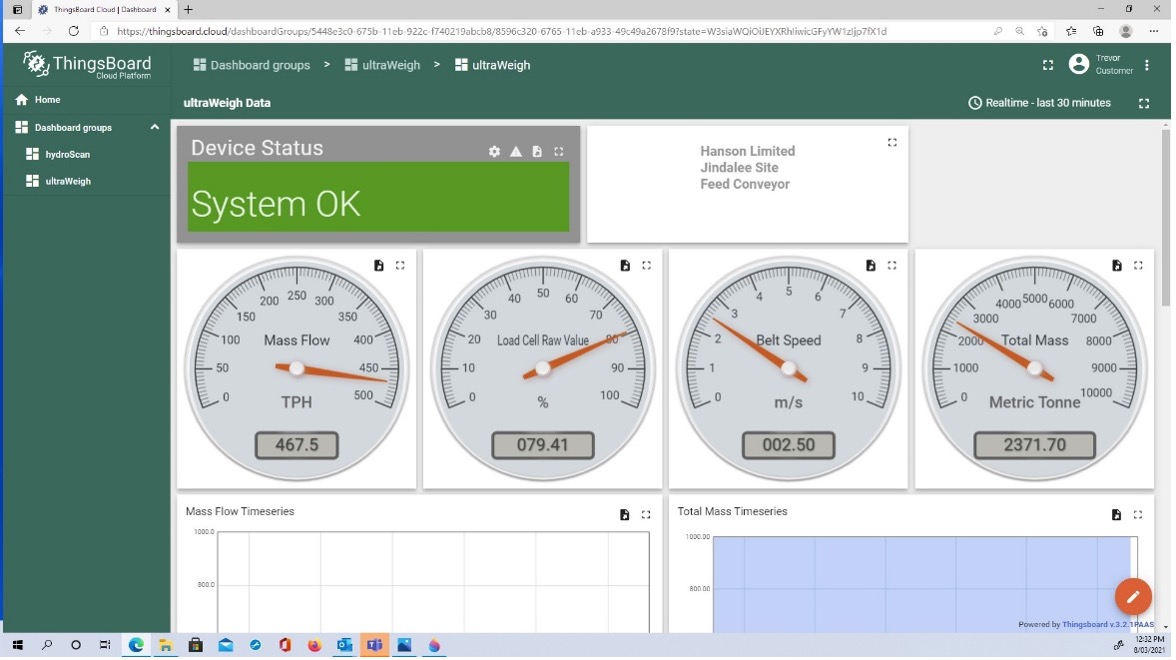

Reducing the maintenance costs of your Load Cell Type Beltscales with ultraWEIGH by Installing a system that includes both automatic zero and remote 4G access

Belt scales can be relatively easily calibrated, however, this is a manual exercise requiring plant downtime and personnel to attend the units and carry out the work. Most belt scales will provide an accurate measurement immediately after calibration, however, the system performance can be prone to drift in time and so calibration maintenance is important. One important aspect of the calibration which affects system accuracy is the zero value. This means that if there is a way to allow automation of the re zeroing ie without the need for operator intervention, this would be a very useful feature. Ultra-Dynamics Pty Ltd ultraWEIGHTM Low Cost Beltscale now includes an automatic zero function. This feature requires the unit to be provided with a “Material Available” signal which is used in conjunction with the speed sensor to indicate to processor that the belt is empty and moving. Once this empty belt condition has been identified by the processor for a minimum period, the unit automatically carries out a zero (empty belt) measurement. This feature allows the zero value to be updated based on prevailing plant conditions which might have changed since the last full calibration and set up procedure.

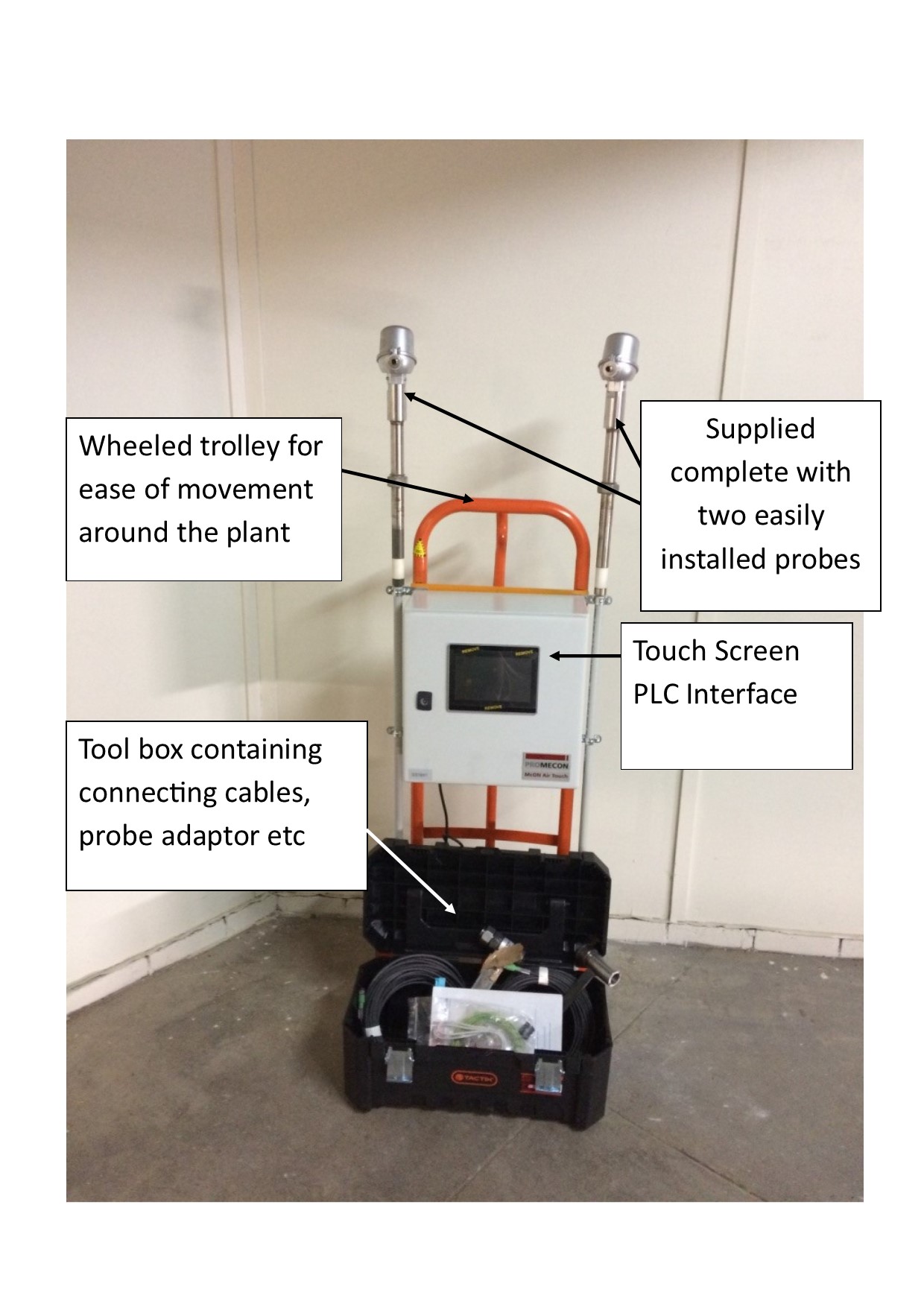

ultraWEIGH Low Cost Beltscale

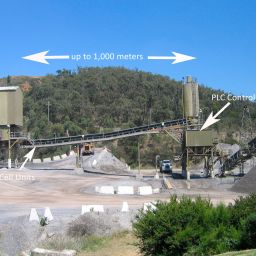

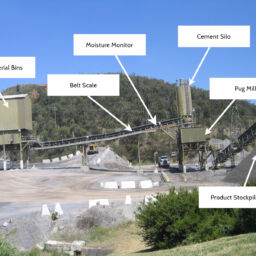

The Ultra-Dynamics ultraWEIGH Beltscale is now available in Australia. ultraWEIGH is a single idler load cell belt weigher intended for applications in which cost is of major concern and a lessor accuracy than that provided by multi idler systems is acceptable

Find out more about the system here.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: