MARK III MAGNASAT NOW AVAILABLE AS AN ALTERNATIVE TO THE RAMSEY COIL TECHNOLOGY

The withdrawal of the Ramsey Coil technology has potentially left a large gap in this area of process measurement. Ultra-Dynamics Pty Ltd is pleased to announce that their highly successful Mark III MAGNASAT technology is a direct replacement for the Ramsey Coil system. The MAGNASAT technology has been extended to include the full range of systems previously supplied as the Ramsey Coil and include:

• On-Conveyor magnetite measurement directly on tonnage rated conveyor belts

• On-Pipe Non Nuclear Density Gauge for density or magnetite content measurement

• In-Tank Slurry/Pulp Level indication.

The application of this type of process measurement system is wide and includes:

• Control of magnetite feed to HPGRs

• Control of magnetite feed to the milling circuit

• Monitoring of magnetite losses in tailings

• Control of the “correct medium” circuit in a coal washery

• Magnetite losses at a coal washery directly measured on a conveyor belt or in pipe

The system is well suited to application in the following plants:

• Cement

• Metallurgical Processing, eg copper, zinc etc

• Iron ore

• Steelworks

MAGNASAT Magnetic Susceptibility Meter – on conveyor system

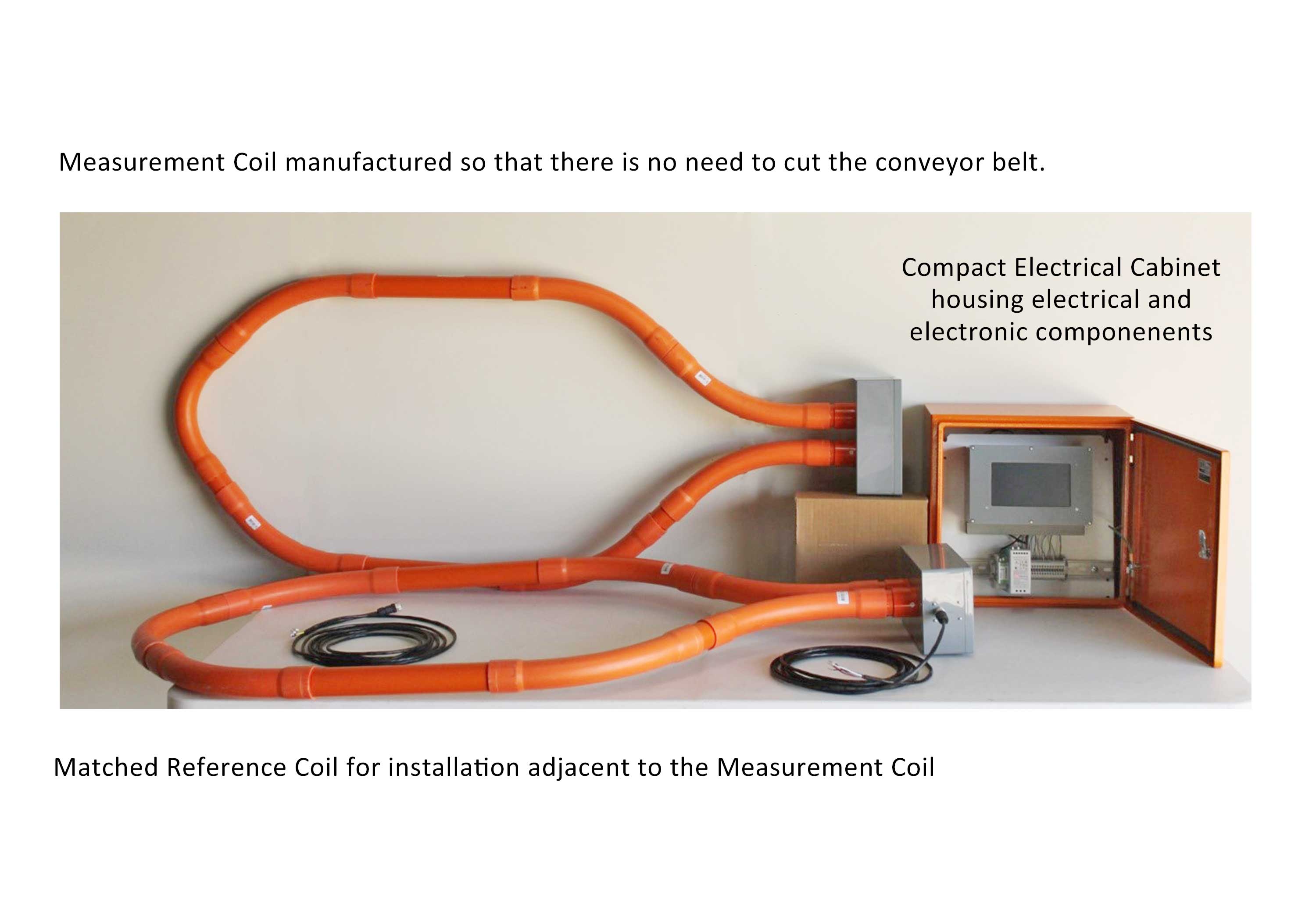

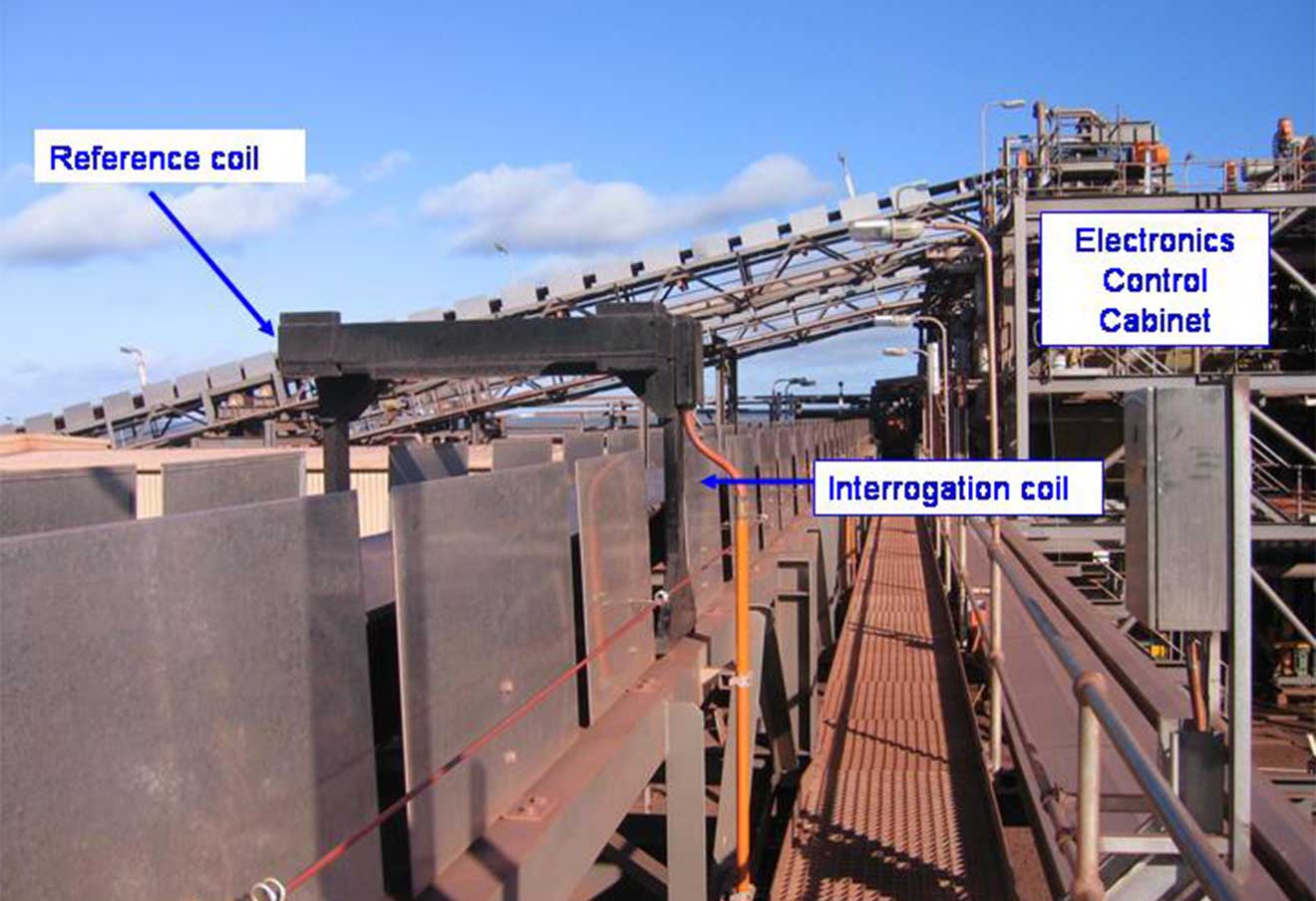

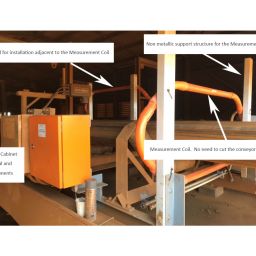

The system has been designed for installation on tonnage rated conveyor belts for the measurement of the metaliferrous content of crushed ore prior to processing. The system consists of an interrogation coil which is installed round the conveyor belt; a reference coil which is located adjacent to the interrogation coil and an Electronics Control Cabinet which houses all the electronic components. As the mineral content changes, these changes affect the electrical field of the measurement coil are is used to determine the metal content of the ore.

The mineral content can then be output to the plant PLC for process control functions. Once the system has been installed, it has to be calibrated, which is usually carried out using an automatic sampling system if this is available. If an automatic sampling system is not available then stop belt sampling can also be used to calibrate the system.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: