The Application of a Moisture Monitor to a Concrete Plant

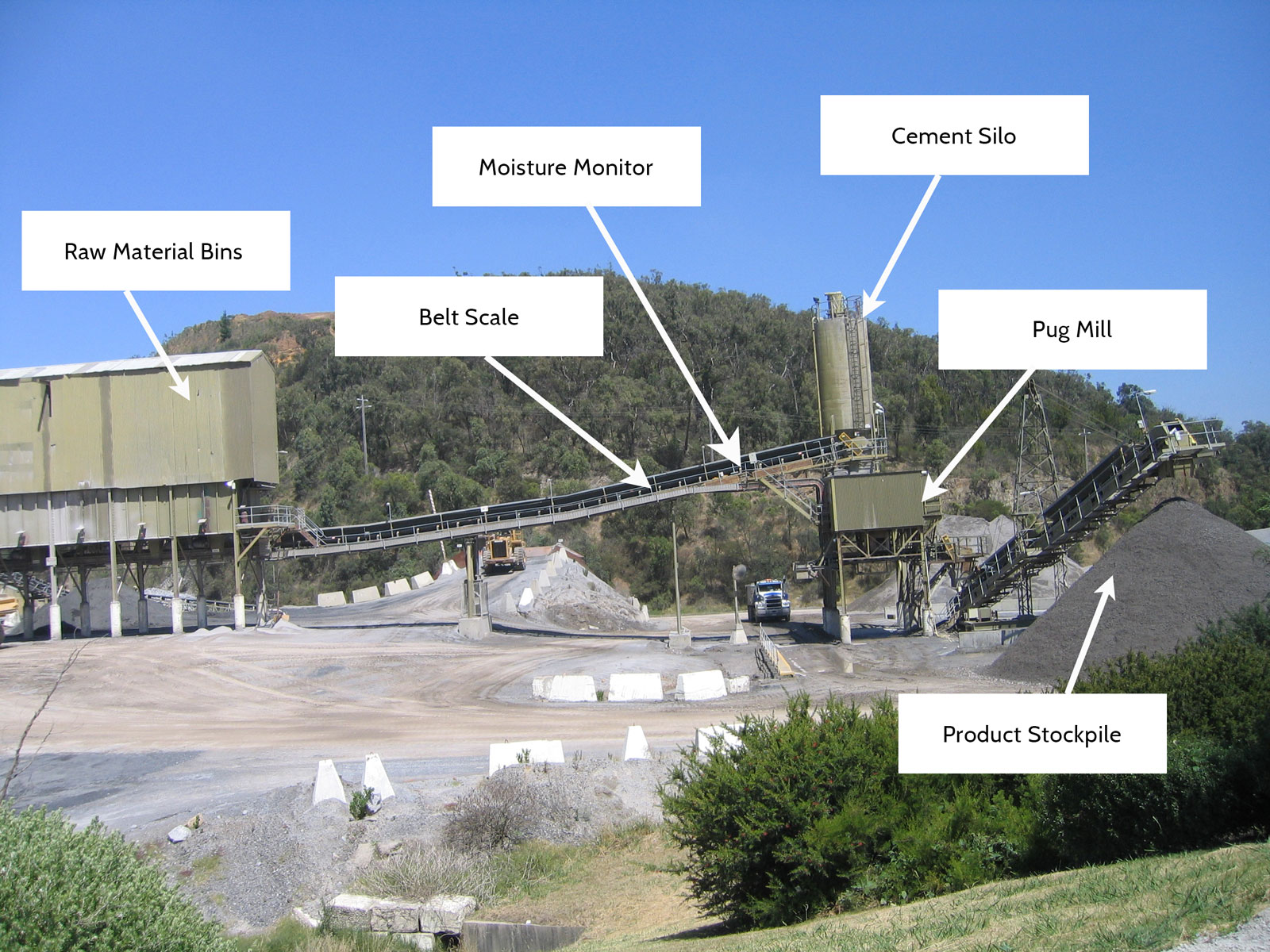

Ultra-Dynamics Pty Ltd recently supplied a hydroSCAN Microwave Moisture Monitor together with an ultraWEIGH Belt Scale to a local concrete plant. The plant had been suffering product wastage due to incorrect product moisture content caused by unobserved excursions in feed material moisture content.

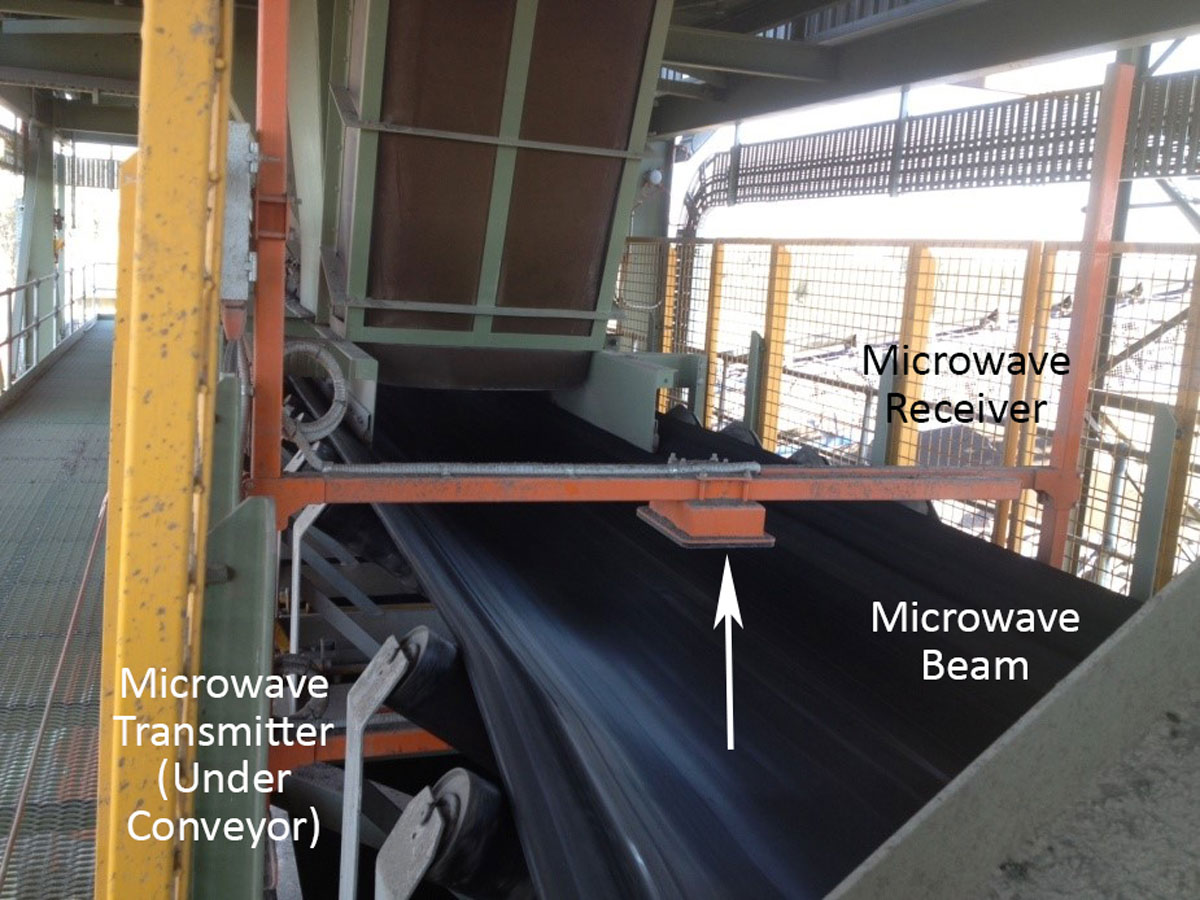

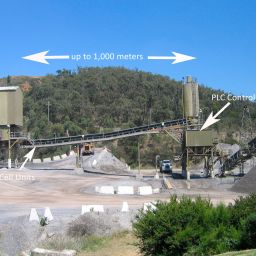

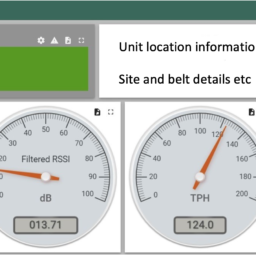

The feed materials are fed sequentially up to the storage bins via an inclined conveyor. The hydroSCAN and ultraWEIGH systems were installed on this conveyor with the output displays located in the operator control room directly above the truck loading point.

Remote access to the systems was provided for Ultra-Dynamics Pty Ltd to access the systems for technical and calibration support purposes. This allowed Ultra-Dynamics Pty Ltd to be able to provide technical support without the need to visit the plant.

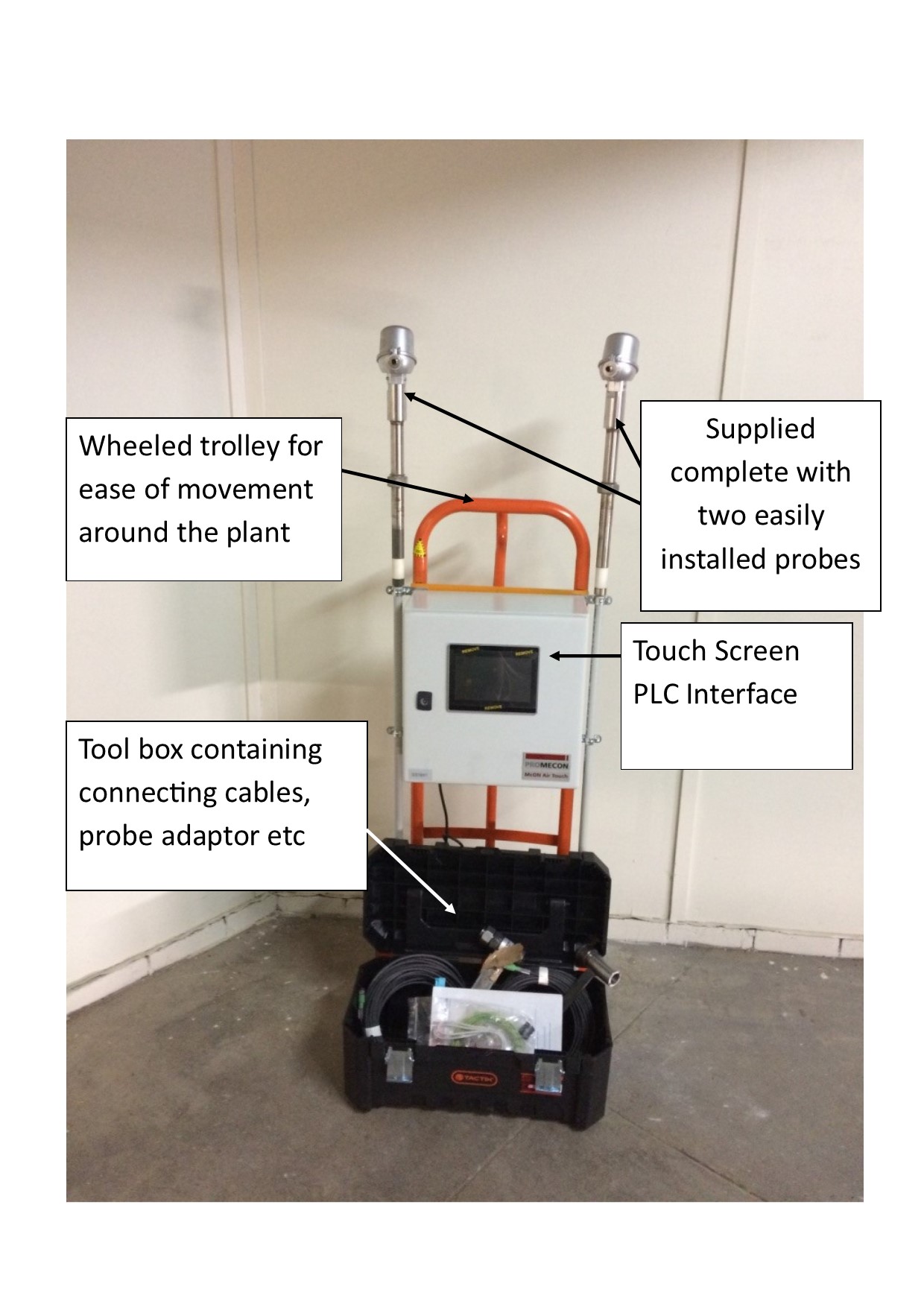

The previous techniques used to monitor the feed material moisture was using the industry standard “frying pan” method. This is slow and time consuming with the reported results only of historical significance and not necessarily a reflection of prevailing conditions. The site required a method for monitoring and reporting the feed material moisture contents in realtime and the hydroSCAN was selected for this purpose. hydroSCAN uses the microwave transmission technique which provides a measurement of the entire conveyor burden not just the surface moisture. It is installed on tonnage rated conveyor belts and provides rapid updates in close to “realtime”.

The ultraWEIGH was used to measure and take account of any changes in mass flow which were reported to be constant, however, operational experience showed that this was not the case and significant changes in mass flow between feed material types was observed.

Once installed the hydroSCAN system was calibrated using the traditional “frying pan” technique and a calibration parameter set installed into the hydroSCAN. The 4G remote access facility was particularly useful in allowing remote update of the calibration as well as the performance of the hydroSCAN.

The hydroSCAN was found to be particularly useful during periods of wet weather when early warning of significant changes in feed material moisture content was observed in advance so that control action could be taken. The hydroSCAN is expected to result in a reduction of spoilage and therefore significant operational cost savings.

HYDROSCAN ON-LINE/ON CONVEYOR MICROWAVE MOISTURE MONITOR

Moisture measurement has always been an important process parameter. Traditionally this has been carried out using the conventional laboratory analysis of a manual sample. Not only is this an expensive and time consuming process but the time taken to provide the result means that the information is only of historical value. During the time interval between taking the sample and reporting the result, operational conditions may have changed so that the reported result is no longer valid to the changed conditions.

Find out more about the system here.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: