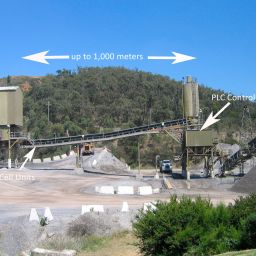

ultraWEIGH Low Cost Beltscale INSTALLATION AT RAVENSBOURNE PLANT

The Hanson owned quarry at Ravensbourne is situated in the mountains 31 km south west of Esk, Queensland, and now home to an ultraWEIGH low cost beltscale after installation at Ravensbourne plant.

Founded in 2000 by Pioneer Construction materials for the purposes of mining the Kaolin clay and sand present at the site, the initial quarry reserves were determined to be 1.2 Million tonnes.

In 2004 Pioneer changed its name to Hanson construction materials and is run by Brett and Casey Purcell.

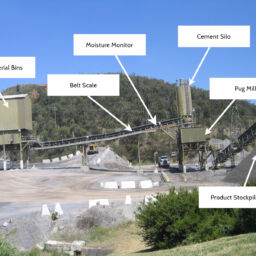

Previously producing clay it now focuses on producing high quality sand for use in Hanson concrete manufacture and landscaping needs. As the sand contains a sizeable fraction of clay which needs to be removed to make a saleable product. The quarry washes 160 tonnes of sand a day to produce 100 tonnes per day of high-quality sand.

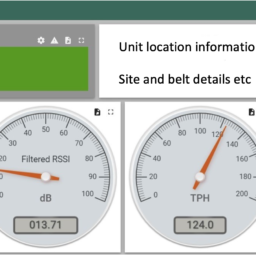

As the site clay level is variable, the site needed to be able to track their sand production for both their own accounting purposes and also to be able to report accurate weekly numbers.

Investing in the ultraWEIGH low cost belt-scale at Ravesbourne Plant has provided:

more accurate data, as previously this relied on a certain amount of educated guess work, and it has also reduced a considerable amount of time spent on paper work.

The ultraWEIGH® low-cost belt scale offered by Ultra-Dynamics was by far the cheapest option with some other units costing twice the price. Ultra-Dynamics is also located in Ipswich which meant they were close should the site need any assistance in future.

It was decided to install ultraWEIGH® on the output belt of the wash plant. Installation was quick and straight forward, only requiring the removal and reinstallation of a single idler unit, along with some short cable runs.

The ultraWEIGH® system has shown itself to be reliable, accurate and easy to use. Using the inbuilt calibration wizard took less than 15 minutes, has only needed initial minor tweaks to get it reading accurately, and since then has not needed adjustment.

Since install Brett and Casey have not needed to count trucks, and the daily accumulated tonnes is noted and logged. ultraWEIGH® has reduced the error associated with their previous method considerably as well as reducing the time spent on paperwork, freeing them up for more important tasks.

“So far, we have only been using the simple functionality of the ultraWEIGH® system to provide daily run numbers. In the future once we have integrated the system into our site PLC, we will be exploring further how we can use ultraWEIGH® to benefit the site”.

On hearing about the solar powered option and the wireless data option that Ultra-Dynamics offers for ultraWEIGH® Casey feels this offers significant cost savings over hard wired options where no cabling already exists. This wasn’t much of an issue for the Ravensbourne installation but he was aware of other sites where the significant cost of cabling can be a deal breaker.

ultraWEIGH Low Cost Beltscale

The Ultra-Dynamics ultraWEIGH Beltscale is now available in Australia. ultraWEIGH is a single idler load cell belt weigher intended for applications in which cost is of major concern and a lessor accuracy than that provided by multi idler systems is acceptable

Find out more about the system here.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: