hydroSCAN® installed at Scope Engineering Quarry at Kin Kin

Scope Engineering was engaged to manufacture and install a screening system taking advantage of the <75 µm fraction of the screenings normally wasted when producing manufactured sand. As these screens are fine, excess moisture will quickly lead to them clogging and shut down of the system until it can be cleared. With this in mind it was decided that an accurate and reliable method was required to monitor the incoming moisture so as to be able to either shut down the screen if the product was too wet, or to give the future potential of diverting excessively wet material.

After a brief search Scope approached Ultra-Dynamics and settled on our hydroSCAN® microwave moisture meter.

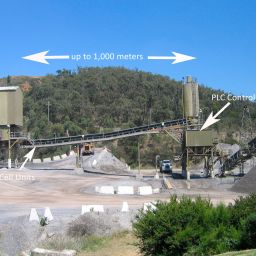

The meter was installed at the top of the input conveyor as shown in this image and connected to the plant PLC.

Installation location of the hydroSCAN® unit

hydroSCAN® operates on the microwave transmission principle. A frame is mounted to the stringers of the conveyor which positions a transmitter below the conveyor and a receiver above the product. A low-power microwave beam is then passed through both the conveyor and the full thickness of the product, water absorbs some of the microwave energy and the moisture content of the product is determined from the change in microwave signal strength.

The advantages of hydroSCAN® are manifold:

- The moisture content of the entire burden is measured, not just the moisture at the surface. This is important especially if there is any vertical segregation of material on the conveyor.

- The distance of the material surface to the receiver is not important so variable burden height will not affect the reading.

- Unlike NIR units, ambient lighting will not affect the reading, the device can be used in direct sun or in full shade.

- The device is non-nuclear and low power, there is no need for special safety considerations during use.

- Critically, dusty environments will not affect the reading. Some other measurement types need to be kept dust free and as such are not suitable for quarry use.

hydroSCAN® outputs natively as 4-20mA but can be fitted with other communications options such as modbus if required.

hydroSCAN® can be powered from either, site supplied 24V DC power or via a 240V AC to 24v DC converter. In cases where there is no power available, a solar powered option is available.

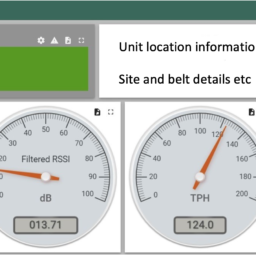

The 7” touch screen can be located either at the measurement location or wired up to 1000m away; There is also a wireless communication option to allow the data to be sent up to 1km away.

Installation is straight forward and is normally completed by site maintenance staff. Calibration will require Ultra-Dynamics technicians, but this can be completed completely offsite with our 4G remote access system.

hydroSCAN MICROWAVE MOISTURE MONITOR – ON CONVEYOR

Conveyor Belt Installation

On-Conveyor Microwave Moisture Monitor

hydroSCAN is supplied with a rugged Support Frame which allows easy, accurate alignment the microwave transmitter and receiver housings on site. The system is also supplied with an electrical enclosure which houses the PLC which is used for data processing.

Find out more about the system here.

Talk To One of Our Specialists

We are striving to be the leading supplier of on-line process measurement technologies and are keen to offer you: